Get Support

+91-80000 13545 , +91-98982 32913

COMPRESSED AIR/GAS DRYERS

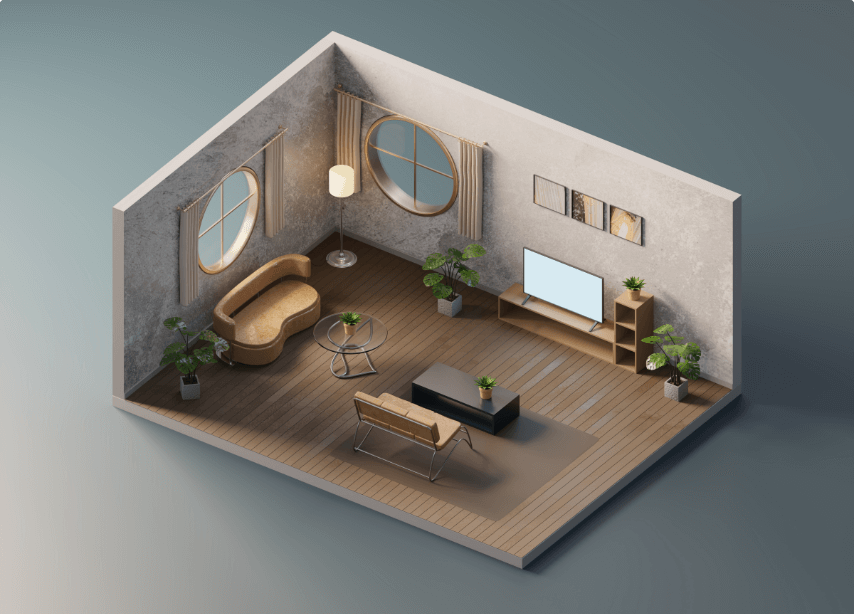

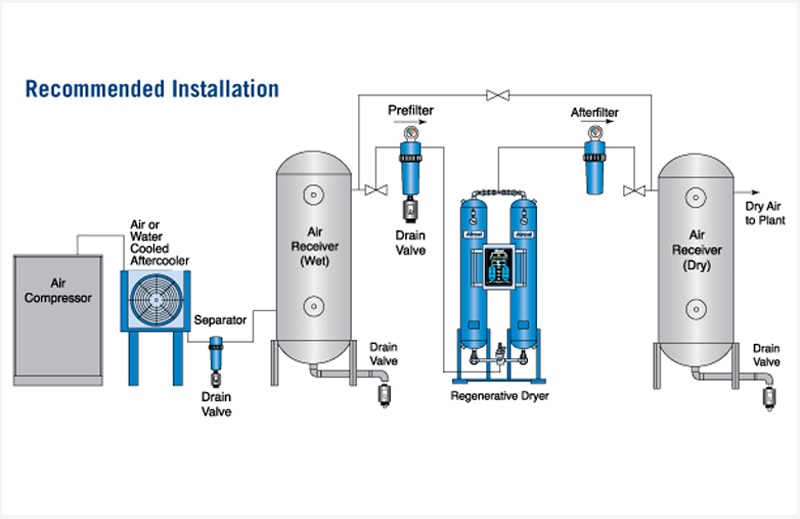

Compressed Air/Gas Dryers are mainly used in industries for various applications in pneumatic tools, pneumatic instruments, pneumatic machines and in a variety of production processes. The consequences of using wet air are rust and scale deposits in steel pipes, increased resistance in flow, malfunctioning of process control instruments, corrosion and damage to electromagnetic valves and pneumatic system, peeling and blistering effect on spray painted surface etc. Thus it will affect the quality of product and lead to excessive maintenance cost. Ideal compressed Air System: Air from the compressor has excessive moisture and contaminants. The sketch below shows a typical Compressed air system to remove these damaging impurities and get Clean and Dry air. When compressed to 7 Kg/cm2g the temperature of discharge air reaches around 140oC. The after cooler and Separator installed after the compressor will cool the air, and removes 90% of moisture and oil. For instance, when the compressor takes in 100 NM3/hr of ambient air at 40oC and 50% relative humidity, at 7 Kg/cm2g the after cooler will condense an average of 30 liters of water in 24 hours. If the outlet air temperature from the after cooler is 40oC, it still contains 8000 ppm moisture. At 45oC compressed air contains 10,500 ppm, at 50oC, 13,500 ppm moisture which is removed by Air Dryer. Therefore, lower the temperature of air at dryer inlet, smaller would be the size of Air Drying Unit.

We manufacture a wide range of Compressed Air Dryers Machine, which are great in demand in domestic and international market.

Few of them are listed below for your reference :

- Heat Reactivated Type Air Dryers

- Heatless Type Air Dryers

- Heat of Compression Type Air Dryers

- Refrigerated Type Air Dryers

- No Purge Loss Type Air Dryers

Applications :

- Replace Bottle Nitrogen

- Air Bearings

- Thermal Test Equipment

- Dry Boxes

- Purge Electrical Boxes

- Pneumatic Instrumentation

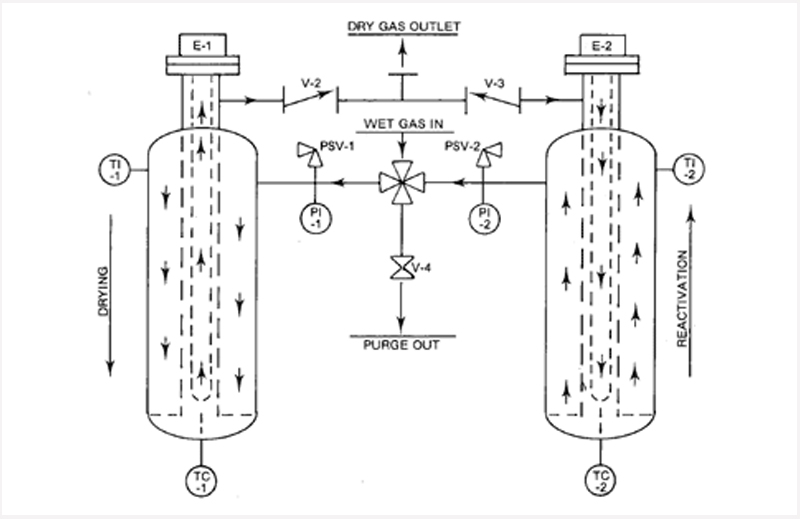

HEATLESS TYPE AIR DRYER

This is the simplest of all desiccant based air dryers. In this dryer two desiccant towers are used. While one tower is in drying, second tower undergoes regeneration simultaneously. Part of dry air coming out from tower in-line goes for regeneration of the second tower. Tower changeover takes place at every 5 minutes by a sequence controller mounted in control panel.

Salient Features:-

- Simple operation.

- Easy to maintain.

- Microprocessor based Controller with Purge Saver.

- No need of heater or cooler.

- Atmospheric dew point of (-) 40 to (-) 60 Deg C can be easily achieved. Simple operation.

| MODEL NAME | E TECH - HD |

| Flow Rate | 5 to 3000 Nm³ / hr |

| Dew Point | (-)40°C to (-)60°C |

| Operating Pressure | 0.5 -50 BAR |

REFRIGERATED AIR DRYER - E TECH - RFD MODEL

We manufacture a wide range of Refrigerated Type Air Dryer The Basic principle is the removal of moisture by cooling air to certain present temperature.

The concept of efficient cooling is removal of heat only. The air first enters into the pre-cooler where the incoming hot air is being cooled by outgoing cold air so as to reduce the heat load of evaporator.The air from pre-cooler enter into the evaporator where further heat is removed by boiling refrigerant like Freon.

Now the air get condensed and this moist air is passed through a moisture separator where moisture is drained out by centrifugal action of air. The moist free air enters into pre-cooler to cool the incoming air.

Salient Features:-

- Simple and compact design.

- Automatic cleaning of condenser.

- Efficient Power Saving.

- Least pressure drop.

- Easy maintenance.

| MODEL NAME | E TECH - RFD |

| Flow Rate | 5 to 1000 Nm³ / hr |

| Dew Point | (-)23°C |

| Operating Pressure | 0.5 -12.5 BAR |

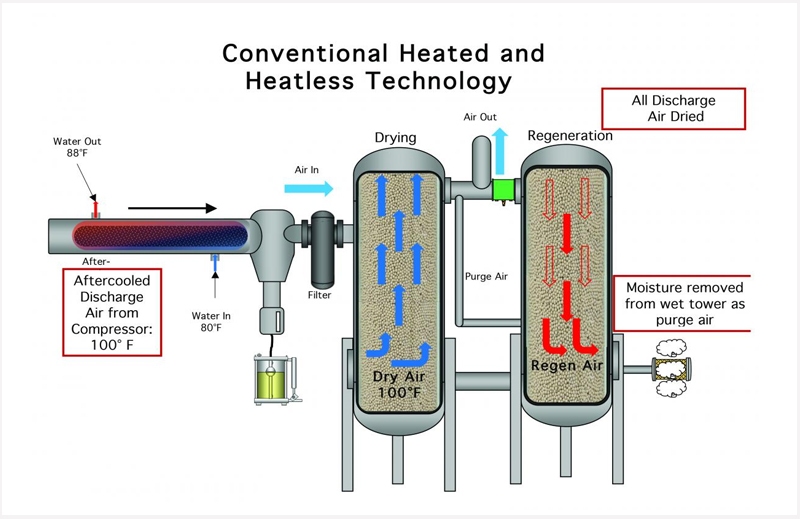

INTERNALLY HEATED AIR DRYER - E TECH - IHD MODEL

This is an improvised version of heatless dryer where purge air loss is very very low due to regeneration is achieved by dry air at low pressure and at high temperature. To achieve this heaters are provided to heat the purge air to around 180 Deg C, which enhances its moisture carrying capacities. This hot purge air at low pressure is passed through the desiccant bed to regenerate with small quantity of purge.

Salient Features:-

- Saving in purge air loss.

- Dew point upto (-) 80 Deg C (atm) can be achieved.

- Compact design.

- Simple operation

- Most economical in the range from 200 CFM – 1000 CFM

- Advanced Version of Dessicant Dryer with Saving in purge air loss.

| MODEL NAME | E TECH - IHD |

| Flow Rate | 5 to 4000 Nm³ / hr |

| Dew Point | (-)40°C to (-)80°C |

| Operating Pressure | 0.5 -50 BAR |

HEAT OF COMPRESSION - E TECH - HOC MODEL

In non-lubricated air compressors, great amount of heat is generated which is lost due to cooling in after cooler. In heat of compression type dryer this heat is utilized to heat the air for regeneration. In this dryer hot compressed air is passed through a heater to maintain the temperature around 180 Deg C, which is then passed through the desiccant bed for regeneration. After taking out the moisture this air is cooled in an after cooler where moisture is condensed and drained out in moisture separator. Then this cooled air is passed through the other tower of desiccant for drying.

Salient Features:-

- No purge loss.

- Saving on electrical Heater load.

- Atmospheric dew point of (-) 600C can be easily achieved.

- Most economical in the range from 400 CFM onwards

Limitations:-

- Can Be used with Oil Free Compressed Air Only.

| MODEL NAME | E TECH - IHD |

| Flow Rate | 5 to 4000 Nm³ / hr |

| Dew Point | (-)40°C to (-)80°C |

| Operating Pressure | 0.5 -50 BAR |

SPLIT FLOW AIR DRYER - E TECH - SFNPL MODEL

To save on purge loss, here part of wet air is circulated through a heater thereby increasing its moisture carrying capacity, which is used for regeneration. In this type of dryer incoming wet air is divided in a distributor. 60-70% of wet air goes for drying while 30-40% of wet air is circulated through a heater thereby increasing its temparature which then takes out the moisture from desiccant bed and then it is cooled in an after cooler where moisture is condensed and drained out in moisture separator. This air is sent back to the distributor where it mixed with incoming air and distributed again.

Salient Features:-

- No purge loss.

- No need of blower.

- No used of external air thus eliminating risk of contamination.

- Most economical in the range from 400 CFM onwards

| MODEL NAME | E TECH - SFNPL |

| Flow Rate | 5 to 4000 Nm³ / hr |

| Dew Point | (-)40°C to (-)80°C |

| Operating Pressure | 0.5 -50 BAR |

LOW PRESSURE AIR DRYER - E TECH - LPD MODEL

Compressed air is passed over a special grade of desiccant in twin tower system. While one tower is under drying cycle, air is passed over an electrically heated other tower and carries out the moisture of this tower. Similarly based on time cycle change over takes place from first tower to second & second to first. The operation is fully automatic

Applications

- Synthetic Fiber Industry

- Chemical Process Industry

- Air Curtains

- Other Miscl. Industrial Applications

| MODEL NAME | E TECH - LPD |

| Flow Rate | 1 to 10000 Nm³ / hr |

| Dew Point | (-)20°C to (-)80°C |

| Operating Pressure | 0.5 -1 BAR |